Introduction

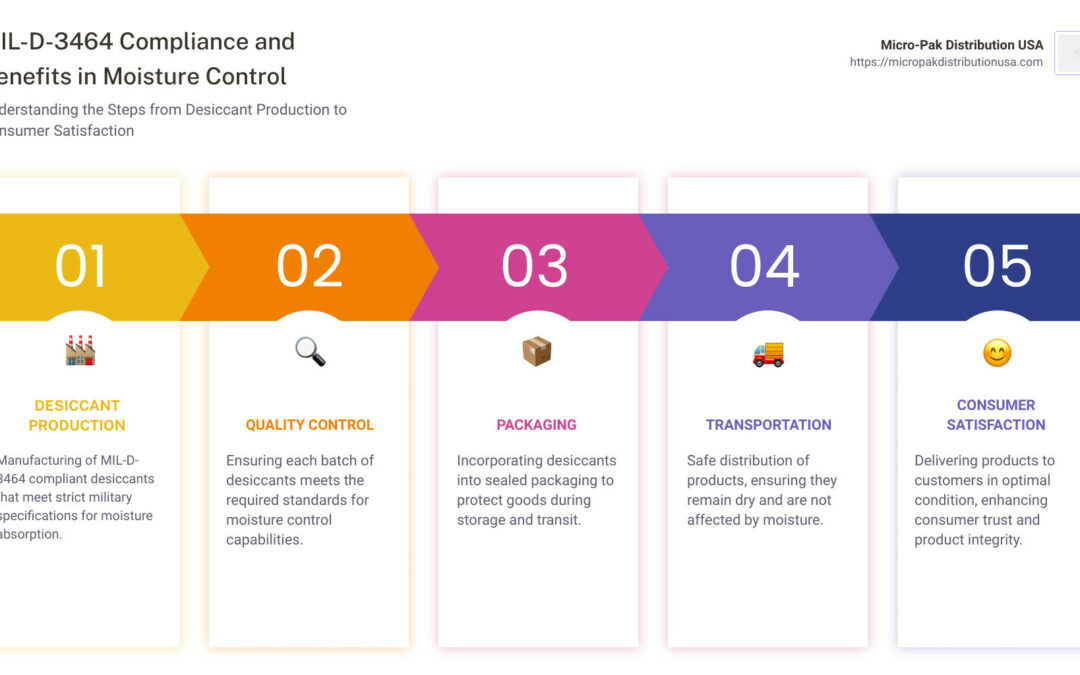

If you’re looking for effective moisture control solutions, understanding MIL-D-3464 is crucial. This military specification outlines the standards for activated, bagged desiccants used in packaging to ensure products are protected against moisture, preventing corrosion, mildew, and other moisture-related damages.

Desiccants play an essential role in absorbing unwanted atmospheric moisture that could otherwise degrade the quality of products during storage and transportation. For businesses in the consumer goods industry, utilizing MIL-D-3464 compliant desiccants signifies a commitment to quality and product integrity, ensuring that items reach customers in the best possible condition.

Key Points:

– MIL-D-3464: Military specification for moisture-absorbing desiccants.

– Purpose: Protects goods from moisture-induced damage.

– Compliance: Indicates high standards of product care.

For those managing consumer goods, adhering to MIL-D-3464 standards is not just about meeting regulatory requirements; it’s about delivering confidence in your products’ performance and longevity.

Understanding MIL-D-3464

When it comes to protecting goods from the damaging effects of moisture, MIL-D-3464 stands out as a critical military specification. This standard outlines the requirements for activated, bagged desiccants used in packaging and static dehumidification. Let’s delve into why this specification is so important and how it serves as a vital tool in moisture control.

Military Specification

MIL-D-3464E is more than just a set of guidelines; it is a rigorously tested standard that ensures desiccants provide effective moisture control in sensitive environments. These environments often include places where high-value items such as electronic components, military instruments, and aerospace parts are stored and transported. The specification ensures that these desiccants are capable of keeping an enclosed space dry and free from humidity that can cause corrosion or mildew.

Chemically Inert Desiccants

One of the key features of desiccants under MIL-D-3464 is that they are chemically inert. This means they do not react chemically with the materials they are protecting. This is crucial for preventing any chemical-induced damage or alterations to sensitive military and aerospace components.

Dehydrating Agents

As dehydrating agents, these desiccants adsorb moisture from the air, trapping it and thereby reducing the humidity level within sealed packages. This process is vital for maintaining the integrity and longevity of products during storage and shipment.

Corrosion and Mildew Prevention

The primary role of MIL-D-3464 compliant desiccants is to prevent corrosion and mildew. By effectively controlling the moisture levels, these desiccants protect metals from oxidizing and organic materials from decomposing or growing mold and mildew. This is particularly important in environments where even a small amount of moisture can lead to significant damage.

Ensuring Product Integrity

By adhering to the MIL-D-3464 standards, manufacturers and shippers can ensure that their products are protected against the unpredictable conditions they might encounter during transport or storage. This specification not only outlines the performance of desiccants but also ensures they are safe and suitable for use with a variety of materials, including sensitive metals and alloys used in military and aerospace industries.

In conclusion, MIL-D-3464 is not just about compliance; it’s about providing a safety net that guards valuable goods against the detrimental effects of moisture. Whether it’s electronic components, military hardware, or aerospace equipment, adhering to this specification means delivering products that perform as expected, without the risk of moisture damage. This commitment to moisture control is essential for maintaining not just the quality but also the reliability and functionality of critical components across various industries.

By understanding and implementing MIL-D-3464E standards, businesses underscore a commitment to quality and product integrity, ensuring that items reach customers in the best possible condition. Let’s explore the different types of desiccants specified under MIL-D-3464 and their specific applications across industries.

The Role of Desiccants in Moisture Control

Desiccants play a crucial role in managing moisture levels in various environments, from electronics packaging to military equipment storage. These hygroscopic substances are engineered to absorb and hold water vapor, which helps maintain dryness and control humidity within sealed packages. This section delves into how desiccants like those compliant with MIL-D-3464 standards are essential in moisture control, focusing on their function, applications, and materials like Clariant and Tyvek®.

Hygroscopic Substance: The Science of Absorption

Desiccants are primarily hygroscopic substances, meaning they have the ability to attract and retain water molecules from their surrounding environment. This property is crucial in environments where excess moisture could damage products or speed up degradation processes. By absorbing moisture, desiccants help create a much drier atmosphere inside packages or storage areas, effectively controlling the relative humidity.

Ensuring Dryness in Sealed Packages

For sensitive items, especially in the electronics, aerospace, and military sectors, maintaining dryness is not just about prolonging shelf life but also about ensuring operational readiness and reliability. Products packed with desiccants meeting MIL-D-3464 standards can withstand varying environmental conditions without succumbing to moisture-related damages such as corrosion or fungal growth.

Clariant and Tyvek®: Leading Materials in Desiccant Solutions

Clariant is a notable manufacturer on the Mil-D-3464E Qualified Product List, recognized for producing high-quality desiccants that effectively control humidity. These desiccants are often packaged in Tyvek® material, known for its strength, tear resistance, and non-dusting properties, making it an ideal choice for packaging critical components. Tyvek® is particularly valued in applications where package integrity and cleanliness are paramount.

Applications Across Industries

The use of desiccants is widespread across various industries. In aerospace and military applications, they protect sensitive instruments from moisture that could affect performance or result in failure during critical missions. In the field of electronics, they prevent condensation that could lead to short circuits or other electrical failures. For machinery, desiccants help in preventing rust and corrosion, extending the lifespan and efficiency of the equipment.

By integrating desiccants into packaging solutions, industries can effectively manage moisture levels, ensuring that products are protected against the detrimental effects of humidity. This not only preserves the quality and integrity of the products but also enhances safety and reliability in their application.

As businesses continue to recognize the importance of moisture control, the role of desiccants becomes increasingly significant. Utilizing materials like Clariant desiccants and Tyvek® packaging, companies can ensure their products are safeguarded against moisture, from production through to delivery. This proactive approach to humidity control is essential for maintaining product quality and customer satisfaction in moisture-sensitive industries.

Types and Applications of MIL-D-3464 Desiccants

MIL-D-3464 desiccants are specifically designed for a range of critical applications where moisture control is essential. These desiccants are activated, bagged, and optimized for static dehumidification, making them ideal for use in environments where even minor fluctuations in humidity can lead to significant damage.

Activated and Bagged for Efficiency

MIL-D-3464 desiccants are activated, meaning they are treated to increase their moisture-absorbing capacity. This process ensures that the desiccants are highly effective right from the start, providing immediate protection against humidity. They are also bagged, which not only facilitates easy handling and distribution but also prevents any potential contamination of the desiccant material, maintaining its integrity and effectiveness.

Static Dehumidification

Static dehumidification is a key feature of MIL-D-3464 desiccants. Unlike dynamic systems that require airflow to function, these desiccants work effectively in sealed environments. This makes them particularly useful in situations where air circulation is minimal or non-existent, ensuring that moisture is effectively controlled without the need for additional equipment.

Applications in Various Industries

MIL-D-3464 desiccants find applications across several critical sectors:

-

Electronic Components: Moisture can lead to short-circuiting, corrosion, and other damage in electronic components. MIL-D-3464 desiccants help in maintaining the necessary dryness to ensure longevity and functionality of these components.

-

Aerospace: In aerospace, the reliability of instruments and machinery is paramount. Moisture can cause failure of essential components. Using MIL-D-3464 desiccants in aerospace components ensures that they perform optimally even under high humidity conditions.

-

Military Instruments: Military gear and instruments must perform reliably in diverse environments, many of which may be humid. MIL-D-3464 desiccants are crucial in keeping these instruments dry and functional.

-

Machinery: In industrial settings, moisture can lead to rust and degradation of machinery. MIL-D-3464 desiccants help in preserving the integrity and efficiency of machinery, reducing downtime and maintenance costs.

These desiccants are not just limited to these industries; they are also pivotal in pharmaceuticals, packaging, and storage, where controlled humidity levels are crucial for maintaining the quality and stability of products.

The use of MIL-D-3464 desiccants in these applications underscores their importance in modern industrial and military operations, where they play a critical role in preventing the detrimental effects of moisture, thus ensuring safety, reliability, and longevity of critical components and equipment. As we move forward into more advanced technological and industrial landscapes, the role of these specialized desiccants will only grow, highlighting their importance in a wide array of applications.

Frequently Asked Questions about MIL-D-3464

What is MIL-D-3464e?

MIL-D-3464e is a military specification that defines the standards for bagged dehydrating agents used in packaging. These agents are chemically inert and are crucial for adsorbing moisture to prevent corrosion and mildew in sealed containers. This specification ensures that the desiccants used in military and industrial applications meet rigorous performance standards for moisture adsorption.

How much is 1 unit of desiccant?

A single unit of desiccant, as defined by MIL-D-3464e, refers to the quantity of desiccant that can adsorb a minimum amount of water vapor at specific relative humidity levels. Specifically:

– At 20% relative humidity, it must adsorb at least 3.00 grams of water vapor.

– At 40% relative humidity, it must adsorb at least 6.00 grams of water vapor.

This unit measurement helps standardize the drying capacity of desiccants, making it easier to specify and use them appropriately in various applications.

Is desiccant hazardous?

Desiccants used under MIL-D-3464, such as silica gel, are non-hazardous. They are inert, meaning they do not react chemically with other substances in normal conditions, which makes them safe for use in a wide range of environments. This non-reactive nature is crucial for applications involving sensitive electronic components or pharmaceuticals, where chemical stability is essential.

These FAQs highlight the importance of understanding the properties and capabilities of MIL-D-3464 compliant desiccants in maintaining optimal humidity levels and ensuring the integrity and longevity of sensitive products and materials.

Alternatives and Substitutes for Desiccants

While MIL-D-3464 compliant desiccants are highly effective for controlling moisture in sensitive environments, there are alternative materials that can be used in less critical situations or where such specific compliance is not required. These alternatives include common household items like cornstarch and paper towels, which possess moisture-absorbing properties.

Cornstarch

Cornstarch is a kitchen staple that can double as a moisture absorber due to its hygroscopic nature. It can be used in small spaces, such as drawers and jewelry boxes, to keep the environment dry. While not as effective or durable as specialized desiccants like silica gel, cornstarch is a biodegradable option that can be useful for short-term moisture control in non-critical applications.

Paper Towels

Paper towels are another simple and accessible option. They can absorb water and help maintain dryness in a variety of informal settings. For instance, wrapping electronics or silverware in paper towels can temporarily protect these items from moisture during storage. However, paper towels need to be checked and replaced frequently as they can quickly become saturated.

Alternative Desiccants

Beyond cornstarch and paper towels, there are other desiccant materials that can be used depending on the specific needs and environment. These include:

-

Rice: Often used in salt shakers to prevent clumping, rice is a traditional tool for absorbing moisture. It is not as efficient as commercial desiccants but can be used in domestic settings.

-

Calcium Chloride: This is a chemical salt that is highly effective at absorbing moisture and is often used in commercial dehumidifying products. It absorbs moisture at a much higher rate than silica gel but can release it back into the environment under certain conditions.

-

Baking Soda: Commonly used to eliminate odors, baking soda also has mild moisture-absorbing properties and can be used in refrigerators and small enclosed spaces.

While these alternatives can provide some level of moisture control, they do not offer the same level of protection as MIL-D-3464 compliant desiccants. They are more suited for non-critical applications where a slight reduction in humidity is sufficient. For industries where precision and reliability in moisture control are crucial—such as in aerospace, military, and high-tech sectors—sticking with certified desiccants is strongly advised.

Transitioning from these common solutions to the next section, it’s clear that understanding the range of moisture control solutions, including innovative products from companies like Micro-Pak Distribution USA, is essential for protecting consumer goods from mold, mildew, and other moisture-related damages.

Conclusion

In the battle against moisture, the importance of effective moisture control solutions cannot be overstated, particularly in industries where the integrity of products can be compromised by the slightest presence of humidity. MIL-D-3464 desiccants represent a critical component in this ongoing effort, providing reliable and powerful moisture adsorption capabilities that are essential for industries like aerospace, military, and electronics.

At Micro-Pak Distribution USA, we are at the forefront of developing and distributing moisture control solutions that not only meet but exceed the stringent requirements of MIL-D-3464. Our products, such as Micro-Pak® Container Desiccants, are designed to offer superior protection by aggressively removing moisture from the air and maintaining an environment that deters the growth of mold and mildew.

Our commitment extends beyond just supplying anti-moisture products. We are dedicated to providing solutions that are also antimicrobial, safeguarding consumer goods from the factory to the retail shelf. The use of our products ensures that items such as clothing, footwear, and leather goods remain not only dry but free from microbial growth, which can cause deterioration and odors.

The consumer goods industry, with its vast array of products and global supply chains, benefits significantly from our comprehensive approach to moisture control. By integrating our products into their packaging processes, businesses can prevent the occurrence of ‘container rain,’ a common challenge during the transportation of goods in varying climatic conditions. This proactive moisture management helps in maintaining the quality and longevity of products, enhancing brand reputation and customer satisfaction.

In conclusion, as the industry leader in moisture prevention solutions, Micro-Pak Distribution USA continues to innovate and support the consumer goods industry with safe, effective, and environmentally friendly products. Our expertise and dedication make us a trusted partner in protecting valuable products against the harmful effects of moisture and microbial growth. For more information on how our solutions can benefit your specific needs, please visit our product page.

By choosing Micro-Pak, you ensure that your products arrive in the best possible condition, no matter the journey they undertake.

Recent Comments